Kamik Makes Big Step Forwaard Using Injection Molding Process

For the same reasons that originally brought it to town — a skilled workforce and a great location among them — Kamik, a leading manufacturer of outdoor footwear, has announced plans to quadruple the size of its operations and double its workforce here.

Based in Lachine, Quebec, Kamik was founded in 1898 and is part of the family-owned Genfoot Co.

In January 1993, Genfoot opened a facility in the Littleton Industrial Park to produce Kamik footwear, and currently the company is splitting operations between there — where the boots are made — and a building on Meadow Street where sewing and stitching is done.

Joe Bichai, who is Kamik’s vice president of manufacturing, said increased demand for Kamik products in general, but especially for those made in the U.S., led Genfoot to begin serious consideration of either expanding its presence here or moving, most likely, out of New Hampshire.

During its deliberations, Kamik was wooed by a number of states, some of which had lower labor costs, but ultimately, the company decided to stay in Littleton, Bichai said during an interview last week.

“We chose Littleton 21 years ago for the same reasons we are choosing Littleton today,” said Bichai, first and foremost because it makes very good sense for Kamik to be close to its biggest market. Kamik footwear is available in many countries, but the U.S. represents 50 percent of total sales, Bichai said, while Canada and Europe each account for 25 percent.

Prior to coming to America, Kamik hired a consultant to look at several communities in the Northeast, but the consensus came down in favor of Littleton because of its experienced labor pool; the fact that the town has its own water and power utility; the lower cost of workers’ compensation insurance versus Canada; and the town’s proximity to Montreal, which is about 2 1/2 hours away.

Once established in Littleton, Kamik grew quickly and now has 100 employees, but that number would increase with the expansion of the physical plant, which Bichai said would consolidate the two sites under one roof while adding a warehouse, expanded recycling area, and a more robust water-recycling system.

At present, Kamik has a combined 30,000 square feet of space in Littleton, but Bichai said the new facility would be built on an undeveloped lot and would be upward of 140,000 square feet. Under a best-case scenario, construction would begin late this year or early in 2015, said Bichai, with completion projected in April 2016.

Although Kamik has consulted with the Littleton Industrial Development Corp., the New Hampshire Division of Economic Development and the town about the expansion, Bichai said it was still, officially, a secret, albeit a widely known one.

Milton Bratz, who chairs the board of selectmen, on Saturday said “We’re very happy that they decided to stay here in Littleton and expand their operation.” The town has several good reasons to be happy.

Kamik owns its land and buildings in Littleton and pays municipal property taxes on them, said Bichai, and would do the same with the new facility. Also, within the first year after the opening of that facility, Kamik would hire 60 additional employees and another 40 in the following year.

Kamik employees earn a competitive hourly wage and also receive benefits including a 401(k) retirement plan, health insurance and — like all Genfoot workers in both Canada and the U.S. — a portion of the company’s year-end profit sharing. With the expansion, said Bichai, they’d also have jobs that were nearly year-round, whereas the current boot manufacturing and sewing operations are seasonal.

The Littleton facility could eventually manufacture 90 percent of the Kamik products destined for the U.S. market, according to Bichai, who added that globally, Kamik is looking to double to triple sales even against formidable competitors such as Columbia and NorthFace.

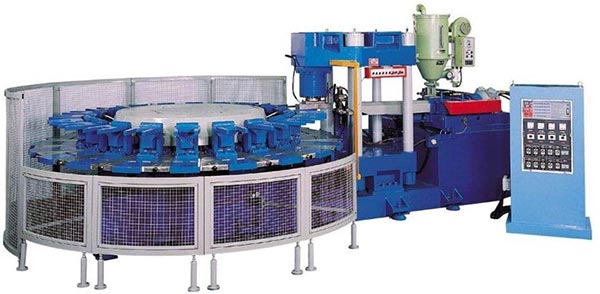

A major factor in Kamik’s competitiveness is technology, said Bichai, noting that for more than 20 years, the company has made boots using an injection-molding process. The Littleton facility has three injection-molding machines; the most recent one was added in July, and Bichai said he just came back from Italy where he was shopping for a fourth.

Having worked with that equipment since it was introduced in Littleton in 1994, Kamik’s Littleton employees have become very proficient with it, said Bichai, which was yet another reason why Kamik is staying put.

“Starting anywhere else from scratch,” Bichai conceded, “would be suicidal.” He downplayed the false allure of low labor costs, saying “It’s not all about labor. It’s about everything else. Labor is 10 to 20 percent of your cost.”

Without naming names, Bichai pointed out that some other footwear manufacturers who moved production overseas are now returning to the U.S.

“When everybody else was leaving,” the U.S., he said, “we were investing,” and those investments are paying off handsomely.”

In the past 12 months, Kamik has seen sales rise by 40 percent, said Bichai, all of which he attributes to having a good product. That product can be purchased at every major chain as well as mom-and-pop retailer in the country.

“The product speaks for itself,” Bichai said, and where Kamik “owns” the market for children’s outdoor footwear — a child who is happy with his or her Kamiks, Bichai explained, is a potential customer for life as well as a recruiter for family and friends — the new “Elements” line of boots that is now hitting store shelves may help the company increase its share of the adult market.

In addition to the patented technology that went into the “Elements” boots, Kamik continues its commitment to sustainability in that 100 percent of boot scraps are recycled to make new boots. Some boots are made entirely of recycled rubber, and the company makes liners and linings from recycled water bottles.

The soles of all Kamik boots are recyclable, and Kamik is increasingly using more recycled materials in its product lines.

“A lot of our customers are asking for as much recycled material as possible,” said Bichai, recalling that just two decades earlier, when the Littleton plant opened, “recycled” was a bad word for retailers, but now it’s extremely positive and, ironically, part of how Kamik has done business all along.